HIGH PERFORMANCE. LONG LIFE. MAINTENANCE FREE.

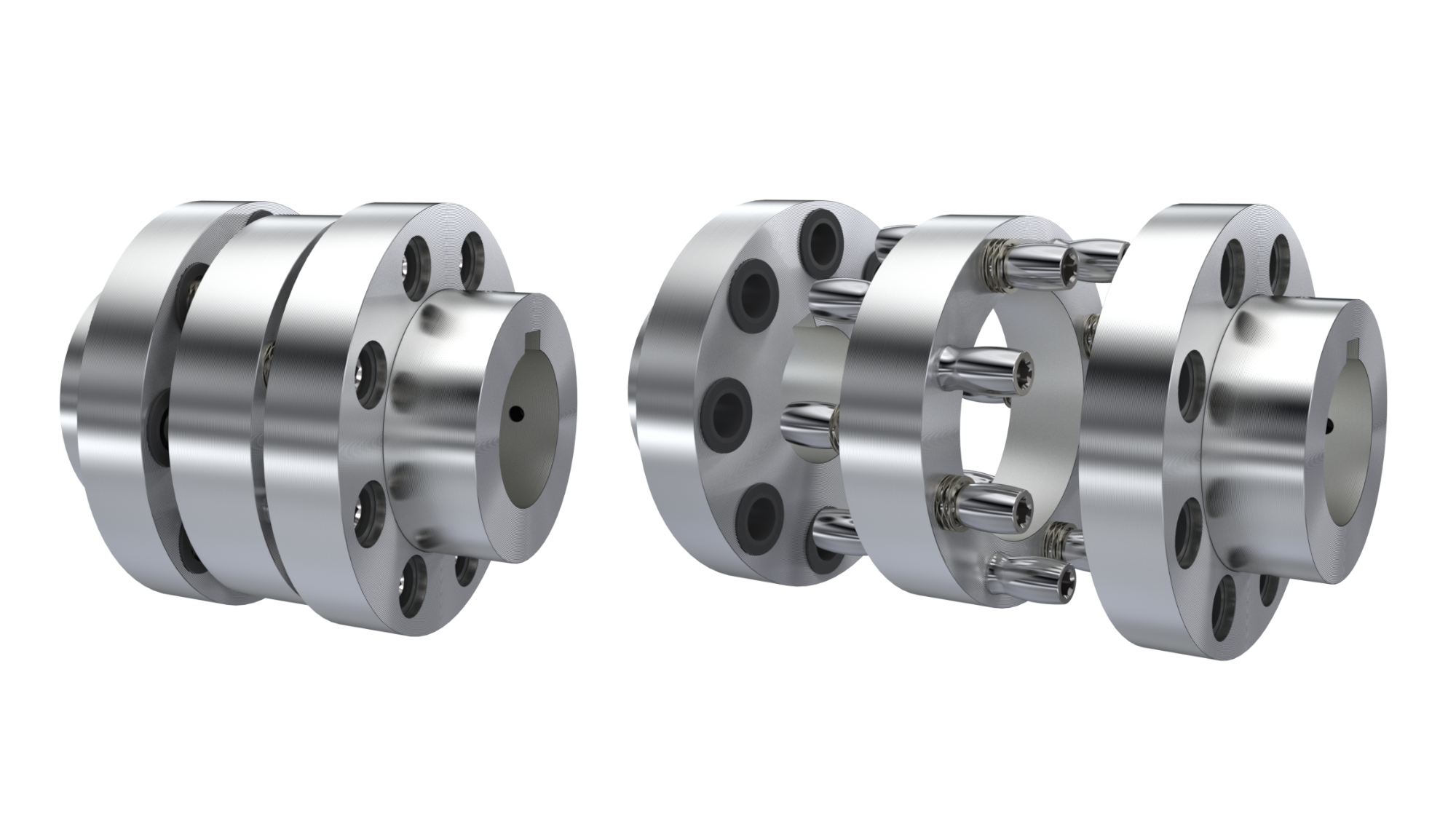

Stainless Steel Flexible Shaft Couplings

Frontline Couplings transmit torque through precision machined barrel shaped pins, which ride within self-lubricated fiber-reinforced polymer bushings. This patented “free-floating” double engagement design gives the Frontline Coupling several advantages.

Advantages

Industry Challenges & Frontline Solutions

These are the most common industry challenges we have encountered working with Reliability & Maintenance teams in the Pulp & Paper Industry and the Solutions that the Frontline Coupling has provided.

FLEXIBLE SHAFT COUPLINGS

FOR THE PULP & PAPER INDUSTRY

Challenge

Solution

UNAVOIDABLE SHAFT

MISALIGNMENT

The Pulp & Paper Industry, with equipment such as Vacuum Pump Trains, Wire Dryers, Bark Bin Screws & Winders, has more challenges than any other industry regarding unavoidable misalignment.

HIGH MISALIGNMENT

TOLERANCE

The “Free Floating” Double Engagement design allows the Frontline Coupling to accommodate unavoidable misalignment while greatly reducing the adverse effect of lateral reactionary forces on the driver and driven equipment.

VERY SHORT PLANNED OUTAGES

Due to the extremely high cost of outages, and the limited availability of maintenance personnel, the servicing of shaft couplings must occur at a very fast pace, over a short period of time and at the lowest frequency possible.

MINIMAL MAINTENANCE

REQUIREMENT

The replacement of Pins & Bushings can be accomplished in a fraction of the time it would take to re-lubricate a Gear or Grid Coupling. For example, a Series 2 Size “K” Double Engagement Coupling on an 800 HP Motor/ Vacuum Pump application could be serviced with new pins & bushings (16 on each side) in about one hour.

COSTLY UNSCHEDULED OUTAGES

The Pulp & Paper Industry, with equipment such as Vacuum Pump Trains, Wire Dryers, Bark Bin Screws & Winders, has more challenges than any other industry regarding unavoidable misalignment.

SCHEDULED MAINTENANCE ONLY

Due to its design, the Frontline Coupling will always maintain a positive engagement between the two Hubs and prevent a forced shut down. The only factor to consider is the degree of wear of the Pins & Bushings.

HIGH MAINTENANCE COST OF

LUBRICATED COUPLINGS

Due to their high power density, Grid & Gear Couplings are widely used and relied upon in the Pulp & Paper Industry. The periodically required inspection and relubrication, however, drastically increases the cost of ownership. After several re-lubrications, the entire coupling needs to be replaced.

CONSIDERABLE LOWER

OVERALL COST

A correctly sized and properly installed and aligned Frontline Coupling will provide several years of maintenance free service and considering that the hubs never need to be replaced the total cost of ownership of the Frontline Coupling is considerably lower than other competing lines.

UNPREDICTABILITY OF

IMPENDING COUPLING FAILURE

Generally, Grid & Gear style couplings fail abruptly without giving any sign of temperature rise, increased noise or higher vibration levels.

VISUAL INDICATION OF

RELATIVE WEAR

A strobe light can be used while the coupling is in service to monitor relative wear of pins & bushings by checking a line marked axially across both hubs’ O.D. at the time of installation.